AEROSPACE

Tooling Solutions

Download Brochure Locate DistributorBUILD STRONGER, BUILD SMARTER

First class tooling solutions for an industry that depends on constant innovation.

AIRFRAME

Small diameter high feed milling used in machining Flap/Slat Tracks and Engine Pylon structures. Great for pocketing, roughing, and slotting in difficult-to-cut materials.

MFH-RAPTOR Mini >>

MFH-RAPTOR high feed mills capable of high metal removal rates are required when machining large titanium parts such as Wing Spars.

MFH-RAPTOR >>

The M-Four (MEW) milling series using PR1535 insert grade is great for pocket milling difficult-to-cut materials such as 15-5 PH or similar stainless steels.

M-Four (MEW) >>

MEC high-efficiency milling cutters are ideal for generating low cutting forces during heavy stock removal on workpieces that are difficult to fixture such as Wing Stringers.

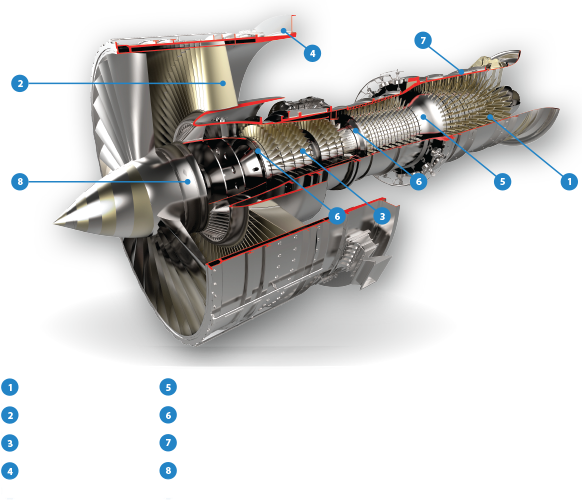

MEC >>ENGINE

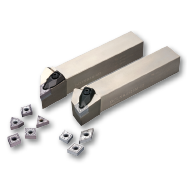

Utilizing the RAD-6 (MRX) radius milling cutters with low cutting forces will reduce chattering for thin cross sections such as Engine Blades & Vanes.

RAD-6 (MRX) >>

Use our PR13-Series insert grades to eliminate edge build up and chatter when machining Fan Casings and other titanium alloys.

Grade PR13-Series >>

Our PR1535 grade is a perfect grade for machining titanium and heat-resistant alloys leaving the high surface finish quality necessary for machining Engine Spools.

Grade PR1535 >>COMPONENTS

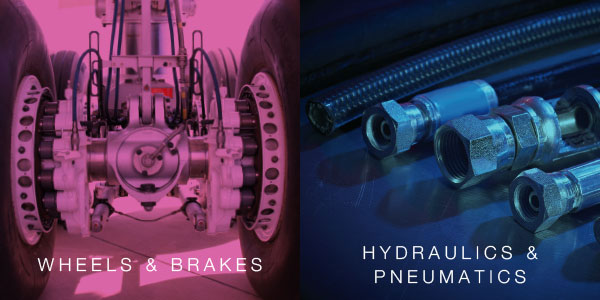

Cutting tools with high wear resistance are necessary to prevent size variations or taper over the full length of cut for Landing Gear applications.

CA5-Series Turning >>

Use TN620 and PV720 cermet grades for high quality steel surface finishes. Surface quality is extremely important with the amount of stress on Wheels & Brakes.

TN620 / PV720 Turning >>

With heavy depths of cut and low feed rates, a large line-up of small tools including our EZ Bars can be utilized effectively in small internal boring of Hydraulics & Pneumatics.

EZ Bar Tooling >>Ready to make a purchase?

Kyocera Precision Tools are sold through authorized distributors throughout North America

Contact a distributor nearest you below

Tell 'em we sent you...

DOWNLOAD BROCHURE

DOWNLOAD BROCHURE © KYOCERA Precision Tools | All rights reserved.

© KYOCERA Precision Tools | All rights reserved.