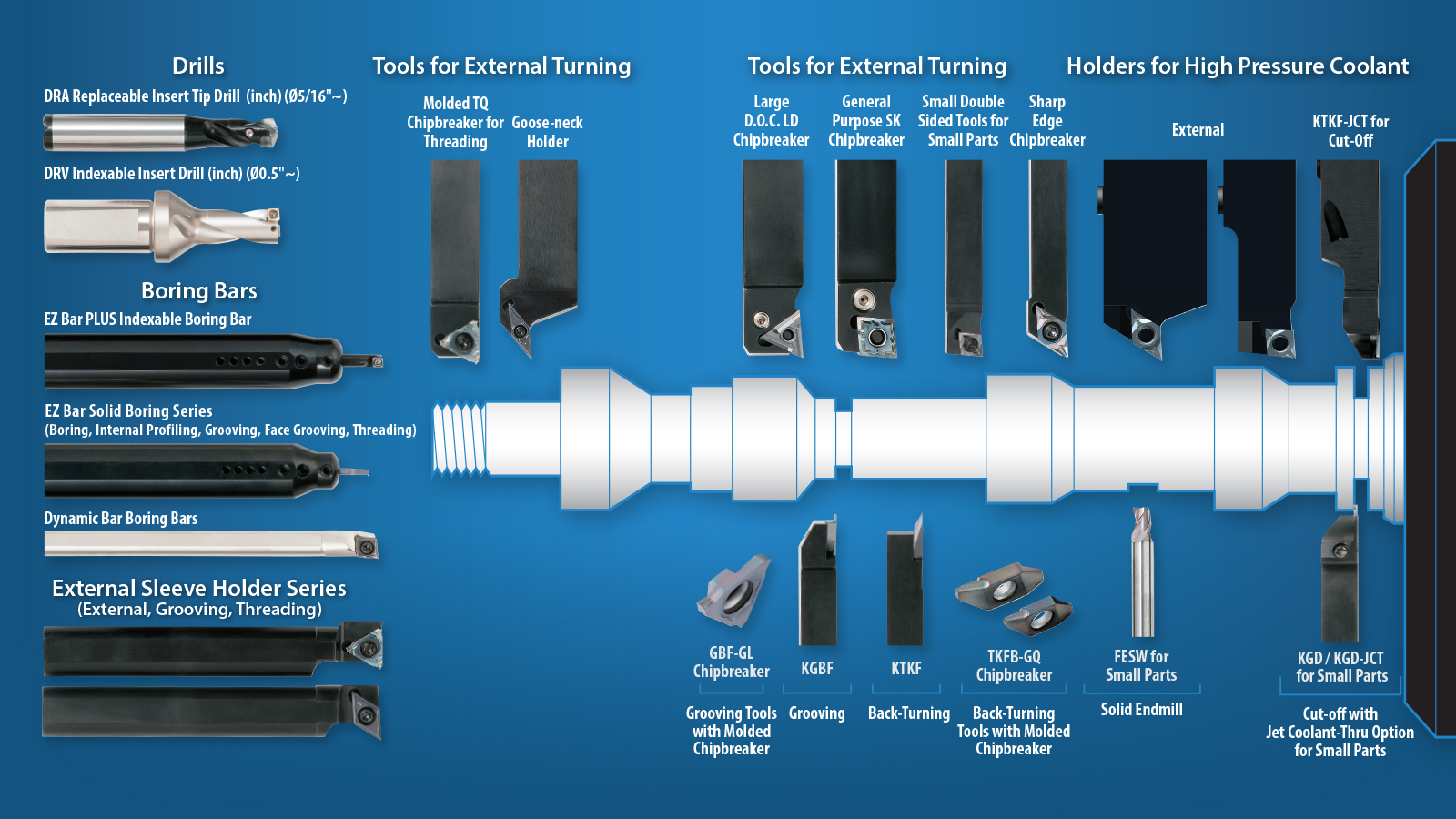

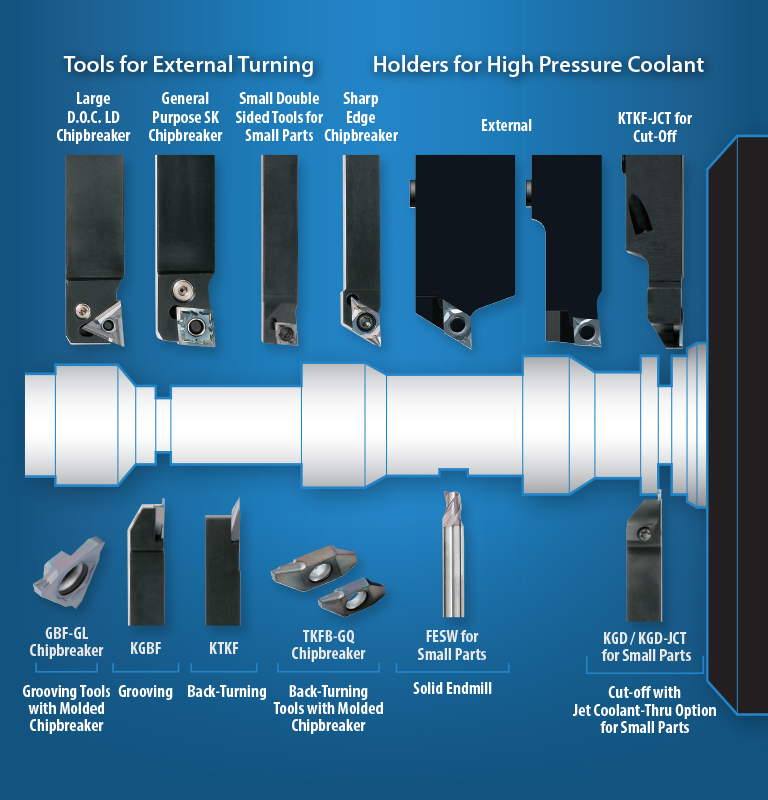

SMALL PARTS

Tooling Solutions

Download Brochure Locate a DistributorPRECISION TOOLING FOR

SMALL PART MACHINE SHOPS

Kyocera provides a wide assortment of dependable, cost-effective, and proven tooling systems for a variety of Swiss machining applications

Optimized Tooling Selection

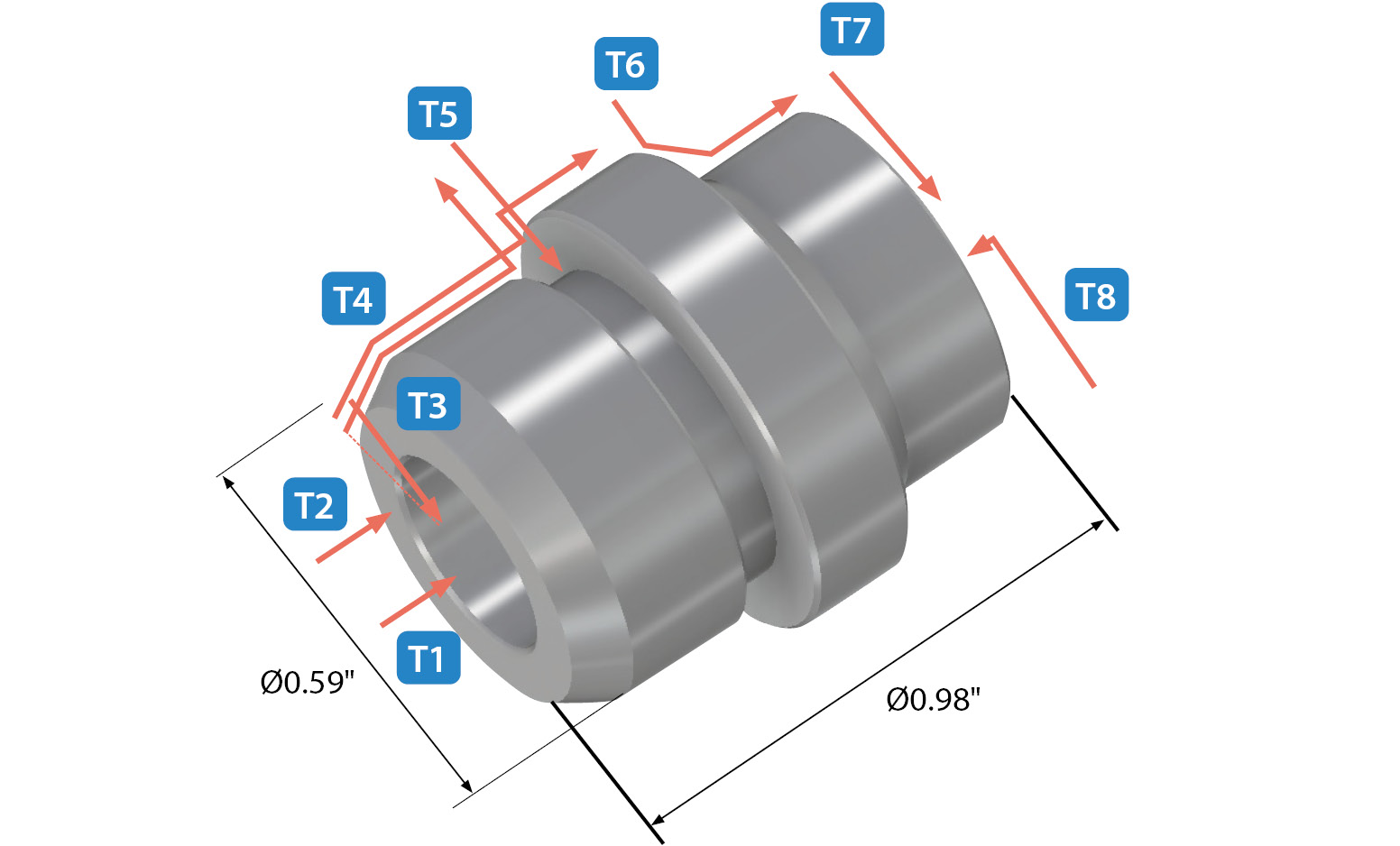

Tooling Demo Injection Core Auto Part (304)

Machining Efficiency

It can be difficult to control chips when machining 304 stainless steel. Due to the number of machining operations required, it is important to optimize the selection of tooling to improve productivity.

Our Tooling Advantages

Stable chip control with molded chipbreakers

Sharp cutting edge for high-quality surface finish

Excellent surface finish in steel Swiss applications "PR1725"

Long tool life with heat-resistant coated carbide "PR1535"

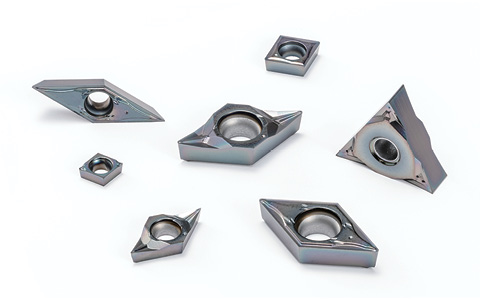

Insert Selection

Kyocera's PR1725 and PR1705 MEGACOAT NANO PLUS insert grades with superior high temperature properties and oxidation resistance maintain ideal performance in steel, stainless steel and free-cutting steel.

Use PR1535 MEGACOAT NANO insert grade as our first recommendation for stainless steel machining. Achieve long tool life and stable machining results with the combination of a tough substrate and a specialized Nano coating layer.

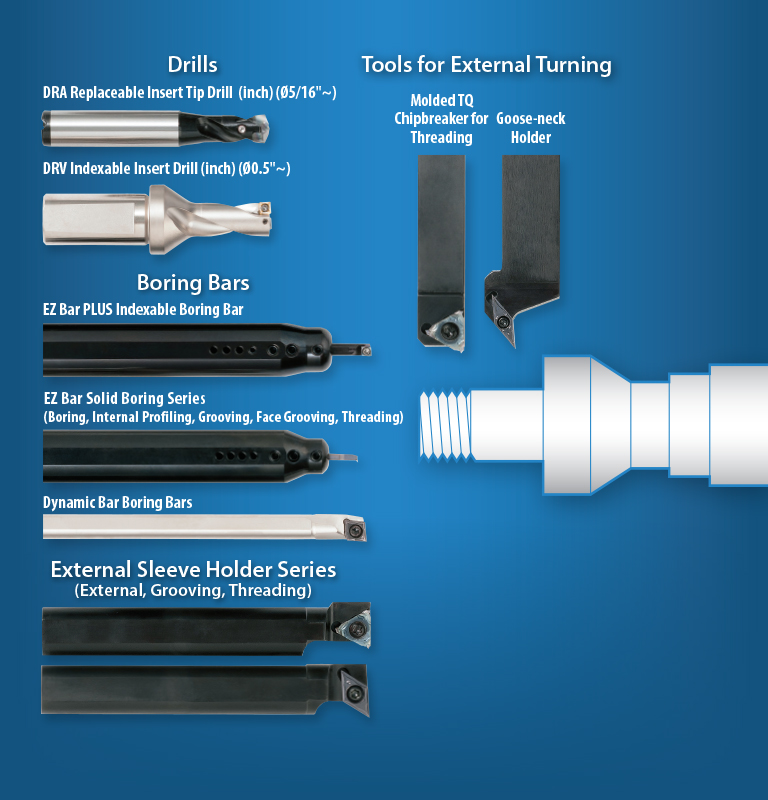

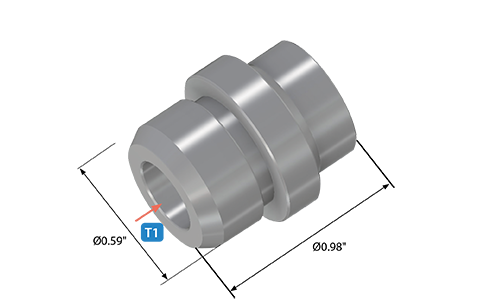

T1

DRA Magic Drill

High precision and high efficiency machining with the DRA replaceable insert tip drill

Drill Body: SS10-DRA080M-3

Insert: DA0800M-GM PR1535

Cutting Conditions: Vc= = 230 sfm, f = 0.003 ipr

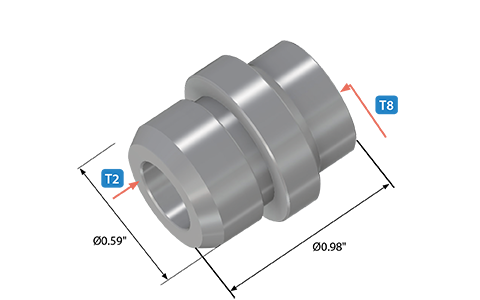

T2

T8

EZ Bar Series

Lineup of high precision adjustable solid bars and micro indexable insert type boring bars

T2

Sleeve Holder: EZH07019CT-120

EZ Bar PLUS (Indexable Type): C06X-SCLCR04-070EZ

Insert: CCGT141105MP-CF PR1535

Conditions: Vc = 200 sfm, D.O.C. = 0.010", f = 0.0016 ipr

T8

Sleeve Holder: EZH06019HP-120

EZ Bar (Solid Type): EZVBR065060-010 PR1225

Conditions: Back Facing, Vc = 200 sfm, D.O.C. = 0.008", f = 0.0020 ipr

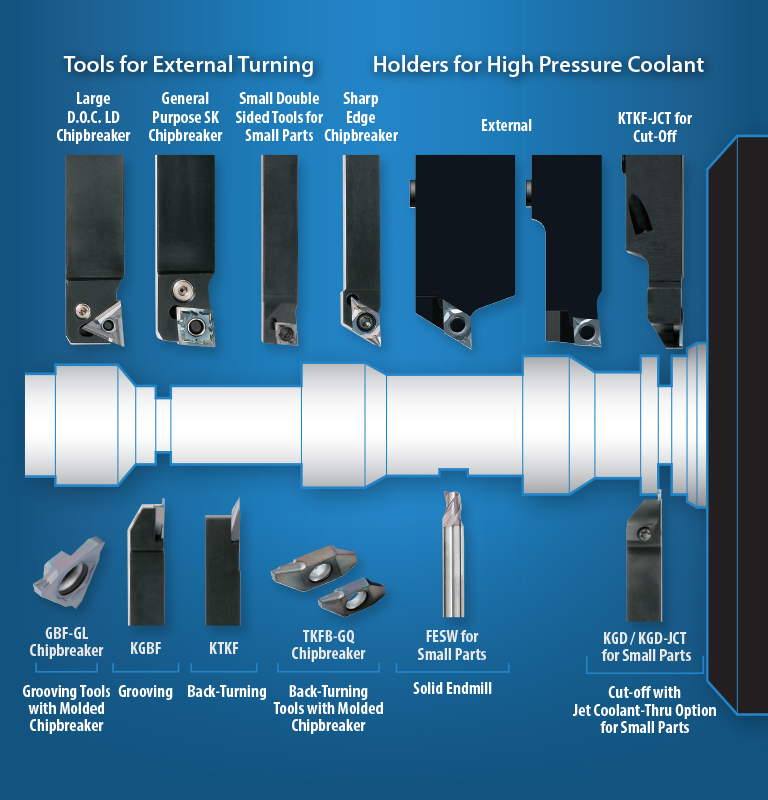

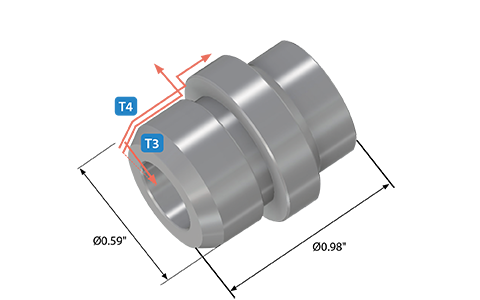

T3

T4

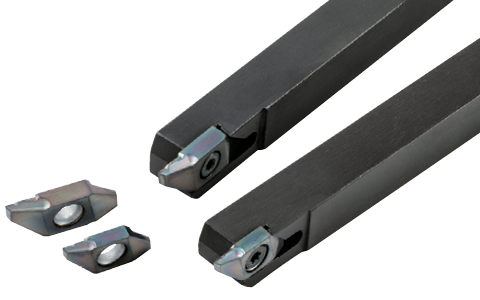

Molded Sharp Edge Chipbreakers

Molded chipbreakers combine sharpness and superior chip control when turning, profiling, or boring

Jet Coolant-Through (JCT / JCTM) holder styles available

T3

Holder: SCLCR1212JX-09FF

Insert: CCGT3251MFP-GQ PR1535

Conditions: Roughing (SK Chipbreaker),

Vc = 230 sfm, D.O.C. = 0.098", f = 0.004 ipr

T4

Holder: SDJCR1216JX-11-F15

Insert: DCGT32505MFP-SK PR1535

Conditions: Finishing (GF Chipbreaker),

Vc = 260 sfm, D.O.C. = 0.020", f = 0.003 ipr

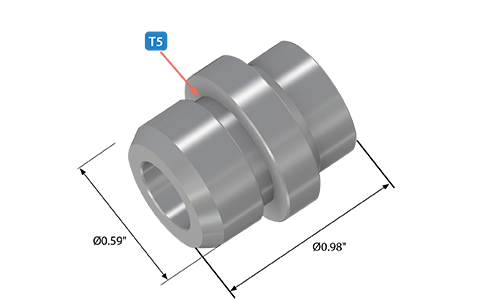

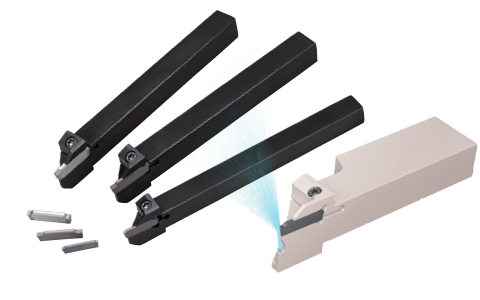

T5

GBF GL Chipbreaker

Molded chipbreaker for shallow grooving maintains smooth chip control

Jet Coolant-Through (JCT / JCTM) holder styles available

Holder: KGBFR1212JX-16F

Insert: GBF32R100-005GL PR1535

Conditions: Vc = 260 sfm, D.O.C. = 0.118", f = 0.003 ipr

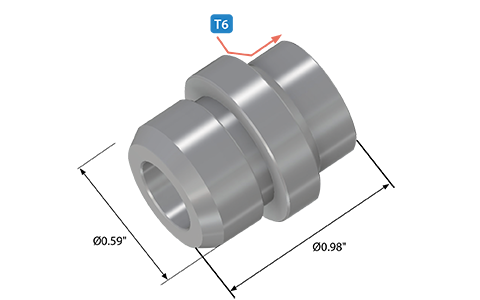

T6

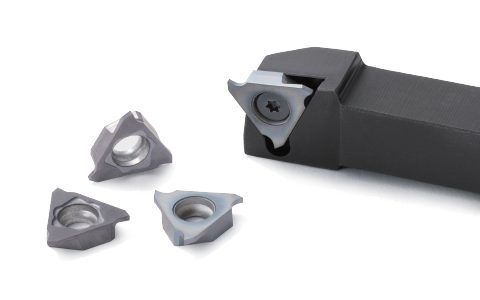

TKFB GQ Chipbreaker

Tool for back turning with molded chipbreaker provides single-pass machining abilities

Jet Coolant-Through (JCT / JCTM) holder styles available

Holder: KTKFR1212JX-12

Insert: TKFB12R28005-GQ PR1535

Grooving Conditions: Vc = 260 sfm, D.O.C. = 0.012" f = 0.0008 ipr

Turning Conditions: Vc = 260 sfm, D.O.C. = 0.118" f = 0.0024 ipr

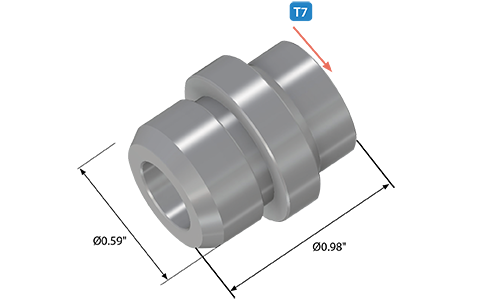

T7

KGD Series for Small Parts Machining

Versatile grooving and cut-off system with good chip control at low feed rates

Jet Coolant-Through (JCT / JCTM) holder styles available

Holder: KGDSR1616JX-2B

Insert: GDM2020N-015PF PR1535

Conditions: Vc = 260 sfm, f = 0.002 ipr

Ready to make a purchase?

Kyocera Precision Tools are sold through authorized distributors throughout North America

Contact a distributor nearest you below

Tell 'em we sent you...

DOWNLOAD BROCHURE

DOWNLOAD BROCHURE © KYOCERA Precision Tools | All rights reserved.

© KYOCERA Precision Tools | All rights reserved.