Time to FEED...

Download Brochure Locate a DistributorKyocera's most versatile high-feed milling series

Chatter resistant and highly efficient in roughing applications

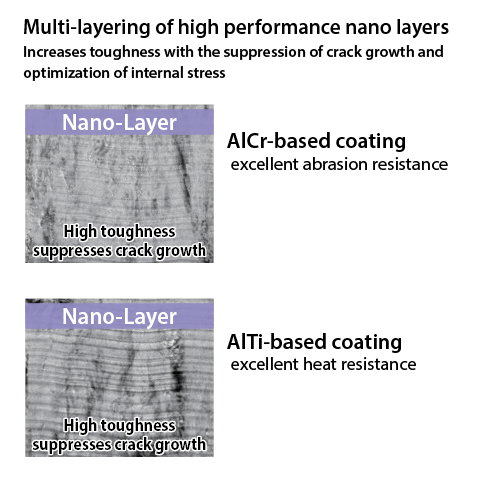

- PR18 Series MEGACOAT NANO EX Insert Coating Technology

Reduced chattering with convex cutting edge design

Reduces cutting forces at initial impact with a convex helical edge design

Cutting force and vibration when approaching the workpiece (D.O.C. = Half of Cutter Diameter)

Cutting Conditions: Cutter Dia. Dc = ∅0.625" , Vc = 490 sfm, fz = 0.024 ipt, D.O.C. = 0.020" (20 Passes): Total 0.394" × 0.630", Dry Workpiece: Stainless Steel

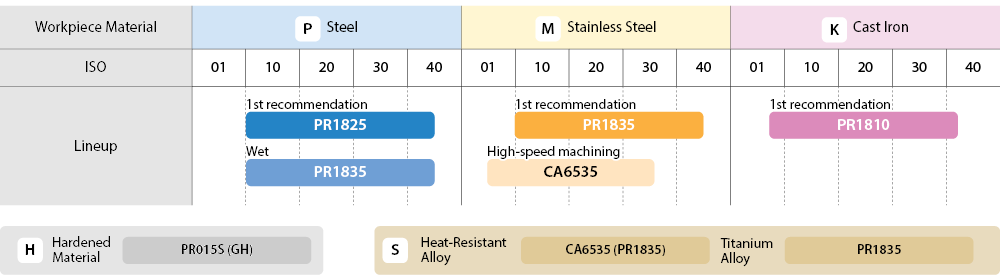

Wide application range for multiple metalworking processes

New PVD coating MEGACOAT NANO EX provides longer tool life

Kyocera's proprietary coating improvements increase tool life longevity and maximize wear resistance

Extensive insert grade lineup covers a variety of materials applications

4 unique insert designs offer a variety of machining options

GM (General Milling)

1st Choice for General Purpose

Multiple Processes

GH

Tough Edge

Excellent Fracture Resistance

LD

1st Choice for Large D.O.C.

Available for Scale Removal

FL

Wiper Edge

Roughing and Finishing Even in Low Horsepower Machining Centers

Word on the street...

"When our sales rep brought this tool in for a test, I was skeptical of just another sales pitch. My operators called me over when they ran it to show me how awesome it was. 300ipm at 0.070 DOC on 1018 steel. Nice chips. Cool tool!

We bought it."

Scott

Machine Shop Supervisor

AGRITEK

"We have slashed our machine time in half and are really pleased after implementing the MFH-Raptor into our production runs. We have had nothing but great results."

Scott

MOLDS & DIES L.T.D. L.C.

"I chose the MFH6000R-14-8T, a six inch diameter feed mill, which has increased my metal removal rate and also allows me to extend the spindle 22 inches into the part without vibration or reduced tool life. Competitors have come in to look at the job, they want to test against the MFH, but never return."

Dustin

PLANT MACHINE WORKS

Ready to make a purchase?

Kyocera Precision Tools are sold through authorized distributors throughout North America

Contact a distributor nearest you below

Tell 'em we sent you...

© KYOCERA Precision Tools | All rights reserved.

© KYOCERA Precision Tools | All rights reserved.